Saab NG900 / 9-3 Fender Replacement

Fenders in the car's original paint color can often be found online, such as with this online used parts database: car-part.com. Mine came from the impressively large stock at Volvo and Saab Dismantlers in Rancho Cordova CA. (From what I read, any fender from 1994-2002 (except the 1994 Convertible) will fit any NG900 or early 9-3...but please check for yourself before ordering.)

Color codes are found on the plate on the inside of the door; use it to find a matching fender. Note that the color may not match exactly depending on paint batch, color fading from the sun, etc. However, it's easier for a body shop to shoot a closely matching fender than a new or non-matching one, especially if it's brought in to the shop off of the car. Despite mine being red, it matched well enough for me without a respray.

How hard is it to replace? Not hard at all. The only special tools needed are a fairly long (~2+ in), thin Torx 40 wrench, and a dremel or grinder that can grind down a washer. There are no welds (the earlier 900's were the ones with welded fenders). The official procedure has you drop the bumper and remove the door, but I'll show you how to get around both with a little ingenuity.

Cost: $100. Time: about 2.5 hours total.

Please - if this information was in any way helpful to you, drop me a line and let me know - email me at

.

.

Connection Points

There are 10 connection points for the front fender (fig 1):- 1-5: along inside of hood

- 6: may or may not be present, along inside of hood

- 7: upper door frame inside door

- 8: lower door frame inside door

- 9: lower mudflap bolt

- 10: underneath bumper

fig 1 |

||

Removing the Fender

- First, open the hood. Remove the side marker light by unscrewing the Torx 25 screw near the headlight, and sliding the whole side marker light assembly forward.

- Remove 3 bolts on mudflap, and leave hanging.(fig 2).

- Remove the Torx 25 screw holding the bumper to the inner fender liner.(fig 3).

- Remove the Torx 40 bolt under the bumper. I did this by flexing the bumper down and out with one hand (fig 4), while unscrewing the bolt with the other.(fig 5)

- Using a sharpie, mark the edge of the fender at the headlight (fig 6) and at the shock mount (fig 7) so that it can be reinstalled without realignment (note that the pictures show me doing this after the screws are out, but you should mark it first).

- Remove the 6 (5 on later fenders) Torx 40's along the fender under the hood (fig 8).

- Note that of the 3 Torx 40's nearest the windshield, 2 are not used for the fender, and the middle one may or may not be present on your fender. (fig 9).

fig 2 |

fig 3 |

|

fig 4 |

fig 5 |

|

fig 6 |

fig 7 |

|

fig 8 |

fig 9 |

Removing the Fender (cont.)

- Open the door fully, and remove the Torx 40 at the top of the door frame near the upper hinge (fig 10).

- Next comes the Torx 40 at the bottom of the door frame near the lower hinge. This will need to be loosened just a bit, so that the door will still close. If it is backed out too much, the door will bind on the screw when closed and may damage the door paint. So, with the door open, loosen the bottom Torx 40 a few turns (fig 11), then gently close the door almost all the way. Insert your hand between the jamb and the door and unscrew the screw the rest of the way (fig 12). (We'll have to use a trick to get that one back in!).

- Pull the inner fender liner away from the fender (fig 13).

- Now the black plastic trim at the bottom of the door has to be removed. On the bottom of the trim, it's held on by 4 plastic nuts underneath the car body; remove these (fig 14).

- Flex the bottom edge of the trim down and off of the bolts. (fig 15). (Note that this image shows the rear bottom trim removed, but that is not necessary to remove this front bottom trim.)

- The top of the trim is held on by the soft rubber weatherstripping; the weatherstrip has a metal channel inside it which grips onto 6 serrated studs that project from the body into the channel. Using the plastic trim piece, pull the weatherstripping and trim free from the studs projecting from the car (fig 16). (Note that depending upon how firmly your weatherstripping is stuck to the studs, you could break the trim. Caveat pullor. An alternate idea might be to attempt to insert a thin flexible blade at the stud positions and pry carefully against padding.)

- The only connection to the car will now be the 2 wires attached to the side marker light. You can now lift the fender and trim assembly free from the car, but note that you cannot pull it very far from the body without stressing the wires. Reach up under the fender and disconnect the wires (fig 17, 18), then lift the fender/trim assembly free.

- The trim is attached to the fender by one body clip (fig 19). The clip on one side has a small loop of metal which keeps it attached to the fender. Bend the loop up and remove the clip, then separate the fender from the trim. Note the orientation of the clip for reassembly.

fig 10 |

fig 11 |

|

fig 12 |

fig 13 |

|

fig 14 |

fig 15 |

|

fig 16 |

fig 17 |

|

fig 18 |

fig 19 |

Replacing the Fender

- First, reconnect the lower trim piece to the fender with the body clip in its original orientation. Push the clip loop back into the hole on the fender so the clip doesn't drift.

- Place the fender/trim assembly onto the body (fig 20).

- Reach up underneath the fender and reattach the two side marker lights.

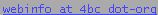

- Make sure half of the split tab on the inner fender liner is above the lower trim, and half is below (fig 21).

- Make sure the clip holding the trim to the fender aligns with the lower bolt hole of the mudflap and thread bolt into clip. Note that this one must be replaced first in case the clip drifts and must be re-set. Replace 2 other mudflap bolts.

- Snap wheelwell edge of fender onto plastic fender liner along its length.

- Flex the lower trim piece onto the studs underneath the car. Replace the plastic nuts.

- Mark the positions of the studs that grip the weatherstripping at the top of the trim piece with chalk on the door frame (fig 22).

- Align the old stud marks on the weatherstripping to the stud locations marked in chalk and tap firmly into place at each stud with your palm; you will hear a distinct 'pop' when they seat correctly.

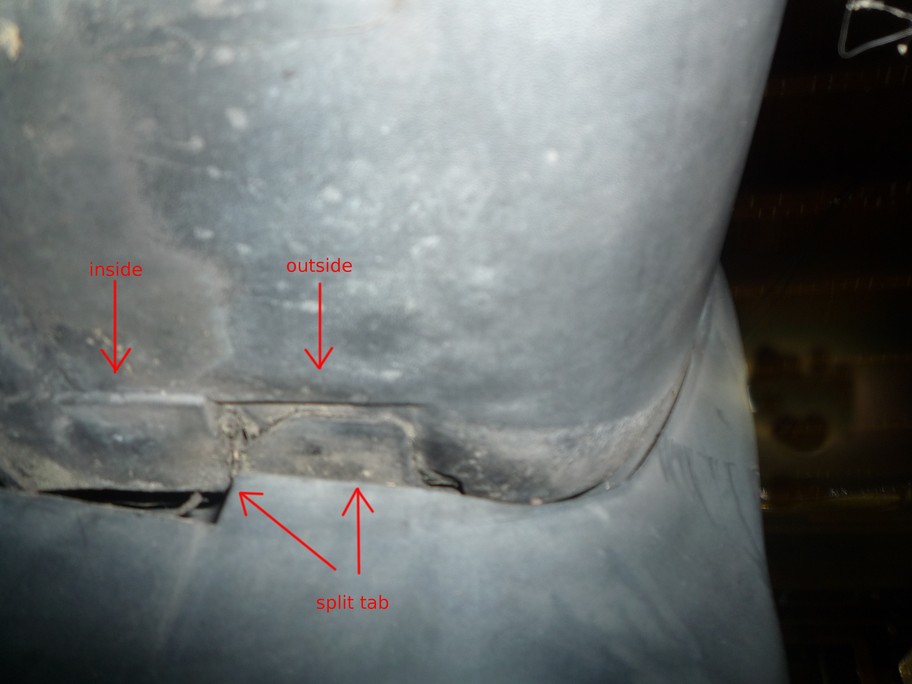

- One of the Torx 40 screws will have to be modified slightly in order to be able to be replaced at the bottom of the door. Using a dremel or grinder, grind off one side of the washer attached to the screw so that it now forms a semi-circle (fig 23).

- With the door open fully, this screw can now be directly placed into the hole at the bottom of the door frame and tightened.

- Replace upper door screw.

- Align fender with marked lines under hood at headlight and shock locations. Replace screws along hood lip. Note that you may need to flex the fender slightly to align fender with both marks.

- Replace screw under bumper.

- Replace Torx 25 screw at bumper corner.

fig 20 |

fig 21 |

|

fig 22 |

fig 23 |